How do Auto Belays Work?

HOW DO AUTO-BELAYS WORK: WHAT'S GOING ON IN THERE?

By Danny Walsh posted in TRUBLUE Technology

For more information on TRUBLUE products, please visit TRUEBLUEclimbing.com

Let's face it, you won't always have the convenience of a climbing partner in today's increasingly busy world. Maybe you don't want to burden your friend to belay you for lap after lap all day while training for your next big wall climbing trip. These are just a couple of reasons why auto belays are so great! These automatic belay systems offer the convenience of climbing of one's own volition and make for an easier introduction to the sport.

But the common climber question is, "How does an auto belay actually work?" After all, you are putting a lot of trust in auto-belays every time you climb on them. The purpose of this post is to demystify auto belays and offer some auto-belay beta that will help you better understand the technology behind each type.

Rock climbing auto belays are categorized by the technology they use to control a climber's descent. The three most common types include magnetic, friction, and hydraulic.

MAGNETIC AUTO-BELAYS:

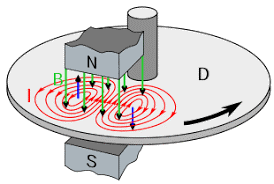

You may have experienced the smooth, repeatable deceleration offered by magnetic braking on roller coasters, trains, and elevators. In a magnetic auto-belay, there are two key elements: conductive rotors and high-strength magnets. During a climb, a large power spring called a retraction spring takes in the webbing (this is the same mechanism that makes tape measures recoil). If a climber falls on the webbing line at any point, the webbing wrapped around the shaft spins the entire internal assembly, creating a centrifugal force inside the drum. This is where it gets interesting.

Several Neodymium magnets are fixed to the outer edge of the webbing spool drum, which maintains a strong magnetic field at all times. When a climber falls onto the webbing line, the webbing spool begins to spin. Centrifugal force pulls the conductive arms on the rotor into the magnetic field which induces tiny electric currents inside the drum. These unique, circular currents (called Eddy Currents) generate their own magnetic field back onto the spinning rotor arms, which opposes the release of the webbing spool. This eddy current braking phenomenon slows a climber's fall to a maximum velocity, resulting in a smooth, controlled descent1. Coolest part? The magnetic brakes are always engaged and only engage further, proportional to a climber's weight.

HYDRAULIC AUTO-BELAYS:

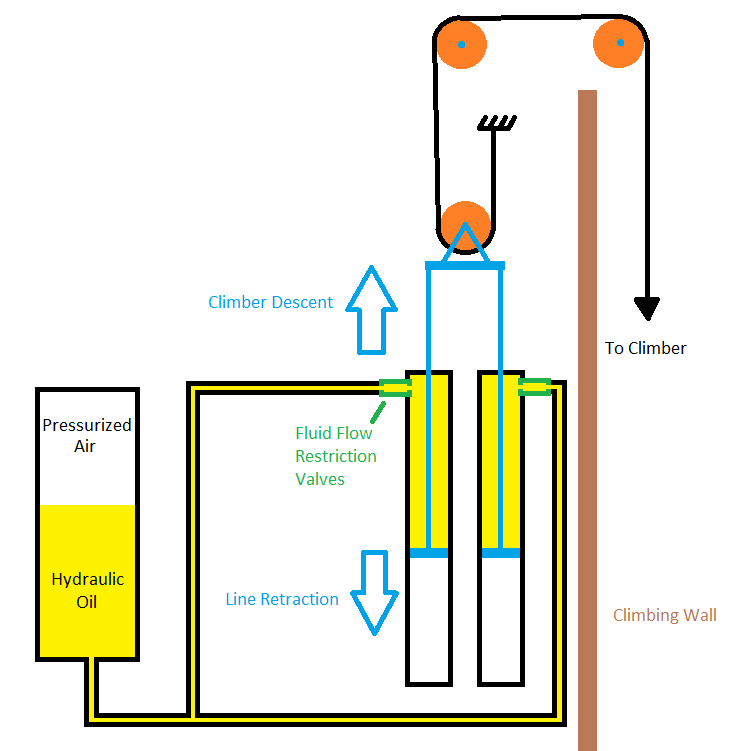

The oldest type of auto-belay system is the hydraulic auto-belay. You often see these in mobile climbing towers at street fairs and carnivals. In this system, a hydraulic cylinder assembly is fixed behind the climbing wall and attached to a cable. Pullies redirect the cable up and over to the other side of the wall where it comes down and clips to the climber so that any fall transmits the force to the hydraulic piston assembly. The hydraulic cylinders use an air-over-oil mechanism that creates positive pressure in the assembly, keeping the cable taut as a climber ascends.

If the climber falls at any point, the force of the climber's fall will create tension on the hydraulic cylinders, pushing hydraulic oil back out of the cylinders through a small fluid flow restriction valve. Since oil is an incompressible fluid, this act of trying to compress the fluid while offering only a small outflow valve is what controls the rate of the climber's descent. Hydraulics takes advantage of the relationship between pressure, force, and area. The system has two hydraulic cylinder assemblies.

The strong upward pull on hydraulic auto belays can be helpful to children getting started, but experienced climbers do not prefer the assistance, and sometimes adults need to pull their kids back down to the ground because the upward pull is so strong. Hydraulic auto-belays used in indoor rock climbing gyms are not portable, and the downsides of the device include the expensive cable replacement, high maintenance, potential for messy fluid leaks, and difficulty of access.

FRICTION BRAKING AUTO-BELAYS:

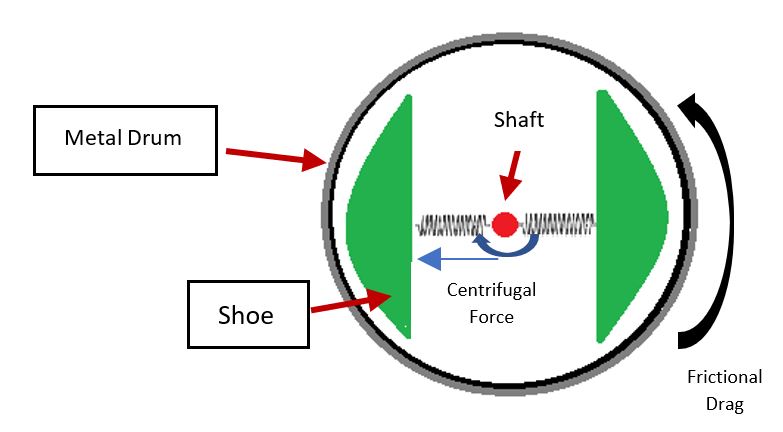

Like magnetic auto-belays, friction auto-belays hang on the top of the wall and use a retraction spring to take in webbing as a climber ascends. Unlike magnetic, a friction auto-belay uses a drum brake, similar to a parking brake in a car. Various models of friction auto belays have been made, using either a length of cable or a length of webbing to attach to the climber. If the brake was always active, the webbing would retract very slowly, so these devices typically use a clutch system to disengage the brake during ascent (retraction).

Both magnetic and friction auto belay devices take advantage of the centrifugal force in a spinning drum but in very different ways. In a friction device, the force causes brake shoes to move outward against a metal drum (image above), creating frictional drag that opposes rotation. These brake pads do mechanical work that slows the release of the webbing and controls a climber's fall, while also releasing kinetic energy as heat and leaving small dust particles (think what happens when you use a pencil eraser, you get rubber particles and it is sometimes hot to touch).

A downside of friction brakes is that the high thermal energy inside the device causes the braking mechanism to deteriorate a phenomenon called brake fade, resulting in increased descent speeds during heavy use. A friction brake will deteriorate as the number of cycles increases because the brake dust itself affects the braking mechanism, and the heat also reduces the amount of friction. This is not the case for magnetic, as there are no contacting, sacrificial wear parts that degrade in proportion to the number of climbs, which is why magnetic auto belays are more often used for high throughput facilities. Additionally, if a foreign substance, like water, gets inside of a friction drum brake, it can change the frictional properties and be catastrophic to the brake mechanism.

WHY MAGNETS CHANGE THE GAME:

Any indoor wall operator wants an auto belay to be easily installed, easily accessed, and easily moved. For this reason, indoor hydraulics have become less common. Secondly, an auto belay must be capable of enduring hundreds of climbs per day in high throughput facilities. A magnetic braking auto-belay endures cycle after cycle without deterioration of braking performance. Friction devices will inevitably heat up and require the replacement of the brake pads. The magnetic technology works climb after climb, as predictably as your compass points north.

The TRUBLUE Auto Belay is the only auto belay to utilize magnetic eddy current braking technology, which offers benefits in addition to reliability and cyclic endurance. Head Rush's patented magnetic braking mechanism allows each device to adjust to each climber's weight and create a consistent descent experience for everyone alike. The more the climber weighs, the more conductive material enters into the magnetic field, and the more braking is applied. Thus, the TRUBLUE auto belays are self-regulating, offering the same descent experience to climbers of all weight types.

So now that you know the different types of auto belays and how each works, go out and teach your friends! Perhaps you'll feel better about climbing on auto-belays the next time you're running laps at the gym.

And check out our YOUTUBE video for a more visual understanding of how to eddy current braking technology works.

FOOTNOTES

1. In physics, Faraday's Law states that when a magnetic environment is changing (such as when a climber's weight spins the rotors through the magnetic field), a resulting electromotive force (EMF) is generated. Lenz's Law states that any current created by an induced EMF always produces a magnetic field that opposes the original magnetic field that created the electric current.